TECHNOLOGY

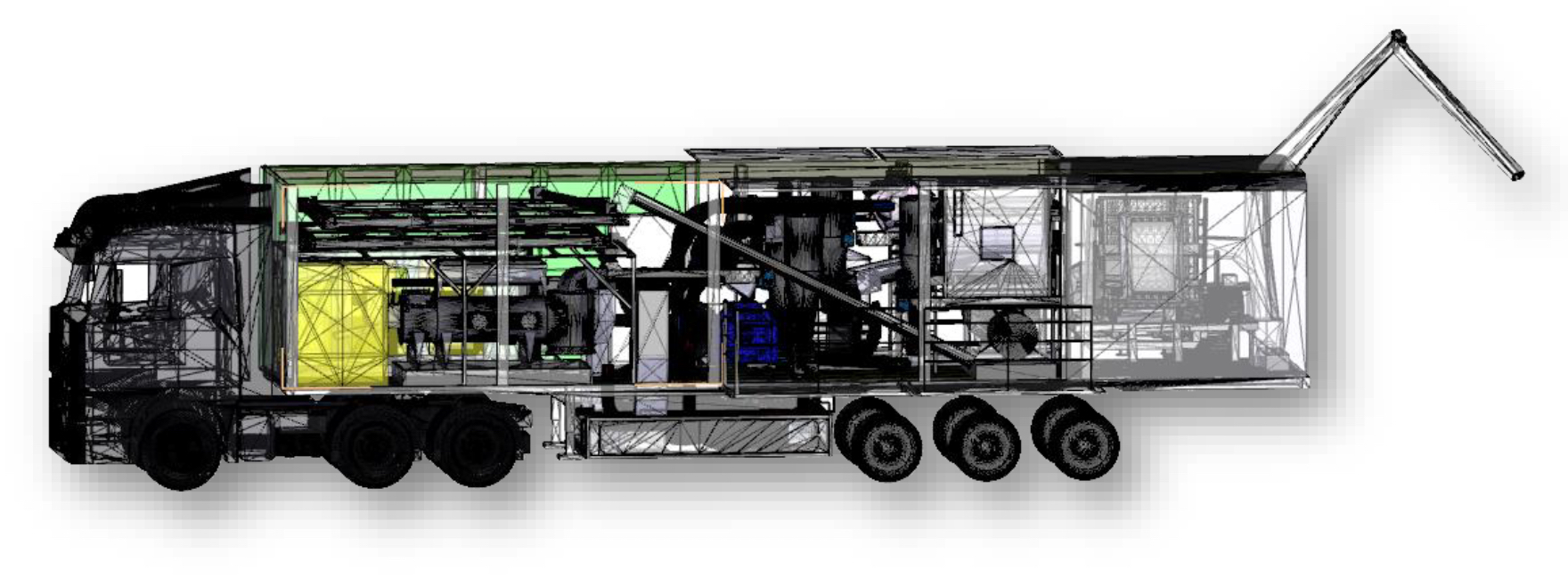

The particularity of the Proxipel technology lies in its ability to combine both mobility and drying of biomass. In addition to the assembly of the various usual elements of a pellet production line, we have specifically developed certain components in-house, in particular for everything relating to the drying of biomass.

MANY ELEMENTS CAN BE ADAPTED TO THE NEEDS OF THE USERS

Unit can be separated into two trailers for hard-to-reach areas, crusher allowing for larger diameters, assembly of the unit on a boat (for treatment of algae or reeds), etc.

ENERGY SELF-SUFFICIENCY

The dryer is self-sufficient. Depending on the moisture content of the incoming biomass, up to 10% of the pellets produced are burned in a burner that feeds the dryer allowing the humidity of the biomass to be reduced to 13%. The residual heat of the generator is recovered to preheat the dryer.

A diesel / biodiesel generator provides the electricity needed to operate the unit.

TECHNICAL DATA

- Nominal pellet production capacity: 1000 kg/h

- Input biomass humidity: up to 50%

- Energy supply: 130 kWe diesel / biodiesel generator

- Fuel consumption: 15-20 l/h

- Weight (without tractor, but trailer included): 29 tons

- Trailer dimension: 13.60 x 2.55 x 4.00 m

- Maximum diameter of the incoming biomass: 20 cm

- Start-up time on new site: 45 min

TYPES OF BIOMASSES

See type of biomasses

Among the types of biomasses that Proxipel can process

- hardwood,

- coniferous wood,

- wood from recycling centers,

- vine branches,

- garden pruning,

- communal pruning,

- forest residues,

- pallets,

- straw,

- hay,

- grain residues,

- mill dust,

- manure,

- coffee grounds,

- grape pomace,

- ...